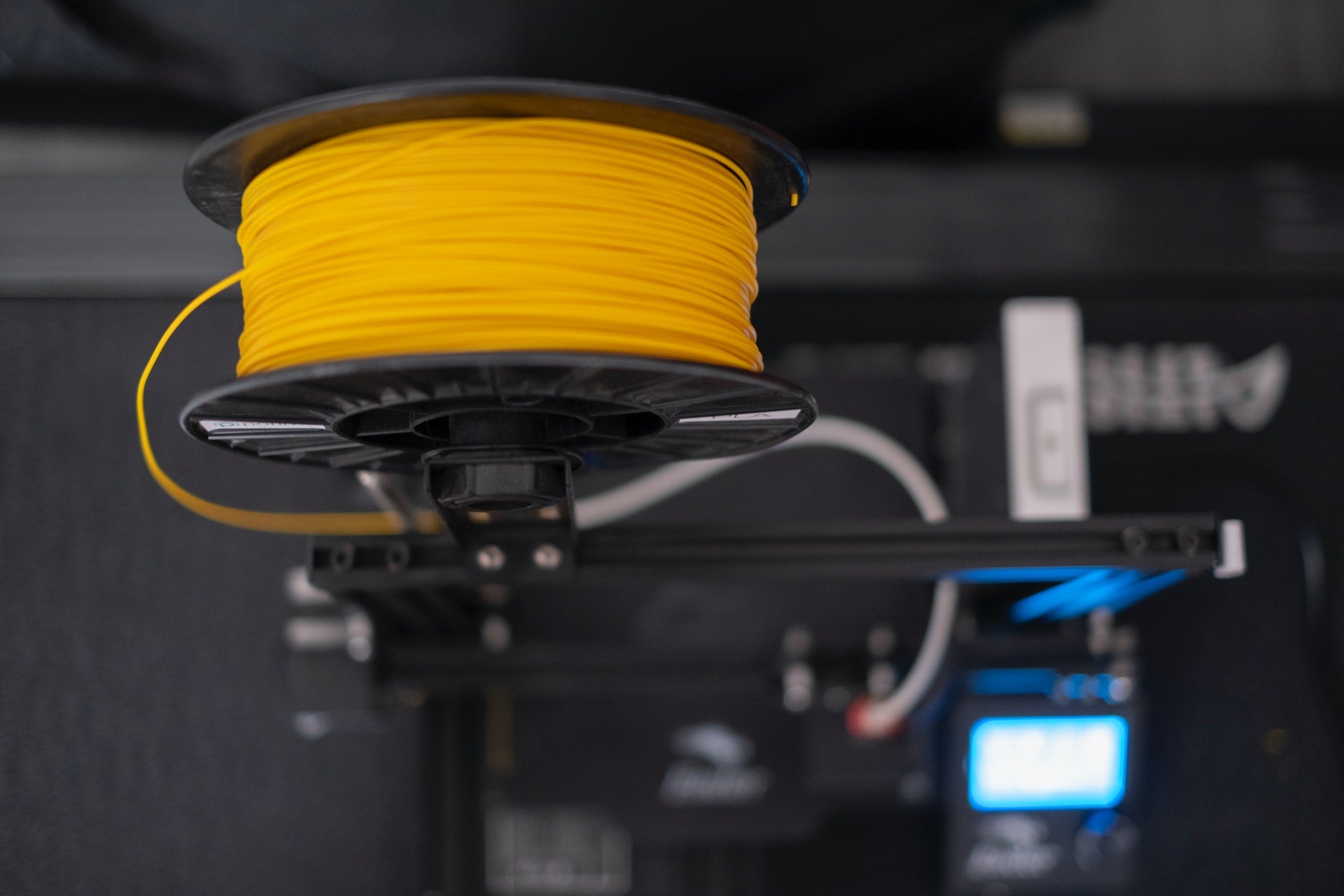

One of the worst things that can happen to you in the middle of 3D printing is filament breaking or snapping off. If you find yourself frustrated from the number of times that this has happened to you, then you’ve come to the right place! Let’s help you unpack the reasons why filament breaks and how to prevent it.

Reasons for filament breaking

If you think your 3D printer is causing the filament breakage, you’re sorely mistaken. It doesn’t matter if you’re using a starter 3D printer or the most sophisticated, such as Ultimaker 3D printers, filament snapping will still happen to you if:

- The filament is stored improperly

- The filament is bloated with moisture

- The spool is spinning too much

- The enclosure is too hot

- The coupler and PTFE tube are jammed

How to avoid filament breaking

1. Store filaments properly

Filaments need to be stored in a cool, clean, and dry container to avoid absorbing moisture from the air. If a filament is left outside, it absorbs moisture which turns it brittle, which then makes it more likely to break during printing.

How do you store your filaments? You can either DIY or buy your storage container. Here are our top picks: Polymaker PolyBox Version 2 and Five Vacuum Sealing Bags with Filament Pump so that your filaments will be protected and stored in an airtight environment when not in use.

For more tips on how to store filaments, read our guide.

2. Dry out bloated filaments

If you left out your filament, then it’s likely that it has absorbed moisture, especially if it’s a hygroscopic filament, such as nylon, polycarbonate, ABS, PVA, TPU, PETG, and most flexible filaments.

Filament breakage is the least of your worries when your filament is bloated. You will also experience printing issues, extruder jams, and low-quality prints.

Fortunately, you can use a filament dryer to dry up the filaments. Here are other ways you to revive wet filaments.

3. Increase resistance in the filament spool

When your filament roll is thinning out, it is more likely to wobble and spin too much during printing. This can cause the filament to break in the middle of the printing.

To solve this, add resistance to the spool by attaching a filament guide or a loop to improve the feeding of the filament through the extruder. You can find ready-made filament guide designs on Thingiverse.

4. Reduce the heat in the enclosure or extruder

There’s such a thing as a too-hot enclosure. When this happens, the printing environment gets too hot that the filament becomes too soft and snaps off while it’s feeding through the extruder.

To cool down the enclosure or extruder, increase the ventilation within the enclosure. You can also try to open the door a bit to allow the air in as a last resort.

5. Change your PTFE tube and coupler

A subpar PTFE tube and coupler can cause clogging to the filament flow. This results in pressure that will break or snap off the filament.

The only solution to this is to get a good quality PTFE tube and coupler. Check out our quality PTFE tubes here.

6. Get quality filaments

Sometimes, no amount of precautions can help if you have cheap filaments. To ensure that your filament never breaks mid-printing, get high-quality ones, such as X3D Pro. X3D Pro filaments have consistently high performance while also being affordable.

Let filament breaking be a thing of the past!

Banish the problem of filament breakage with these tips! For filament orders and inquiries, send us an email or a chat.