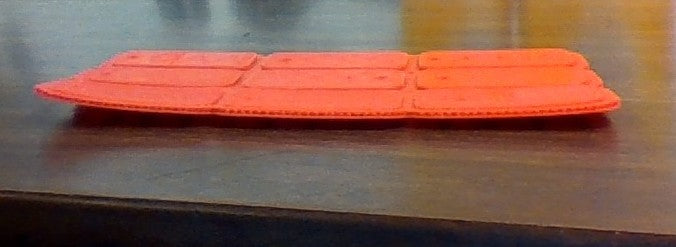

Warping is a common side effect for plastic-based 3D printing filaments. If you find warping on the edges of your print, it could also affect its adhesion on the print bed and cause cracks in the upper parts.

Solution:

There are several fixes to this issue, ranging from increasing print bed adhesion to adjusting the print bed settings.

- Increase print bed adhesion: To prevent the edges from lifting, rub a thin and even layer of stick glue on the print bed.

- Make your print platform plastic-conducive: Plastic filaments thrive on heated print platforms. Set the temperature to just below the plastic melting point. You could also change your print bed to one that has improved adhesion. Finally, you can run through the bed calibration process to make sure that it is levelled.

- Improve contact between the bed and model: Add rafts or platforms in order to increase contact between the bed and the model.

- Amp up the print bed temperature: Level up the print bed temperature in increments of 5 degrees until you hit the sweet spot. You should also tweak the fan cooling settings and raise it to .75 mm before letting it switch to full power.