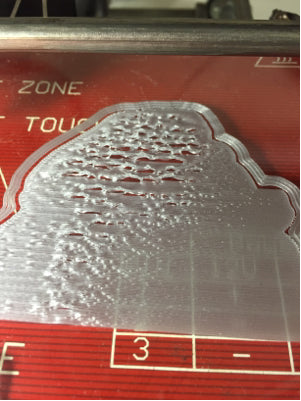

Instead of a complete pattern of infill, you see that some parts are broken or missing. It is usually caused by choosing the wrong settings within the slicing software. Some cases are caused by a slightly clogged nozzle.

Solutions: Here are ways to fix the broken infill issue:

- Tweak the infill settings: Get to the root of the problem immediately by adjusting the infill’s speed, density, or pattern. The speed can affect the quality of the print, so the speed may be too fast if you’re getting lapses in your print. On the other hand, the infill density could only be set at a minimum of 20%, otherwise, you’ll experience issues. Larger models are recommended to have a higher infill density in order to get enough support. Finally, changing the infill pattern is sometimes enough to fix your problem. You’ve got plenty of choices, so choose the pattern that works best for your print.

- Unclog your nozzle: When there’s a slight nozzle blockage, there may be less flow for the internal structure. Check out our helpful tips on unclogging nozzles.