The support structure is important, especially if you are printing complex prints. It serves as beams to support the overhanging parts of your print from sagging or falling.

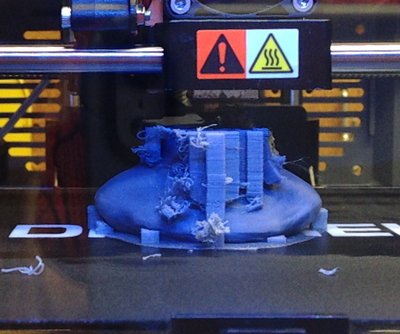

If you find that the support structure is starting to look uneven, stringy, or cracked during mid-print, it may be that the supports are failing. When the supports fall apart, it becomes a domino effect as the filament being extruded thereafter will ruin your print.

There are several styles of support structures that are just meant to be flimsy but easier to remove. Lines and zig zags are such examples. On the other hand, densely designed supports such as grids and blocks tend to be more rigid but are harder to remove.

Aside from weak support, there are several reasons why the support structure is not coming out great. Platform adhesion is also crucial to ensuring that supports are bonded to the print platform. Avoid printing supports without it.

Supports made of lower quality or older filaments also tend to break down easily.

Finally, loose nuts and bolts can also affect your printing since it can cause the printer to move or vibrate more than usual.

Solution:

While there is nothing that can fix your ruined, there are several solutions to make sure your next one comes out smoothly.

- Boost the support thickness: We mentioned above that thick supports tend to be more rigid and stable, giving your print a steadier platform.

- Opt for more rigid support designs: There is nothing wrong with using thin supports especially if the overhangs of your print isn’t that heavy. However, if you know that your print would need plenty of support, choose denser support structures.

- Always print supports with platform adhesion: When printing supports, always add platform adhesion so that the mounts can have something stable to adhere to.

- Add in-model supports: When printing out an overly tall print, adding a tall block to support your support structure makes a world of difference. Taller support structures are vulnerable to breaking down, so it needs a stable foundation to support it. A support for your support.

- Use only high-quality filaments: You can be sure that anything printed with old or cheap filaments is bound to fail. Don’t use filaments that are beyond their usable lifespan.

- Check if the nuts and bolts are tightly screwed. Loose nuts and bolts can cause your 3D printer to shake and wobble, which can ruin your supports.