Description

When PLA just isn’t enough

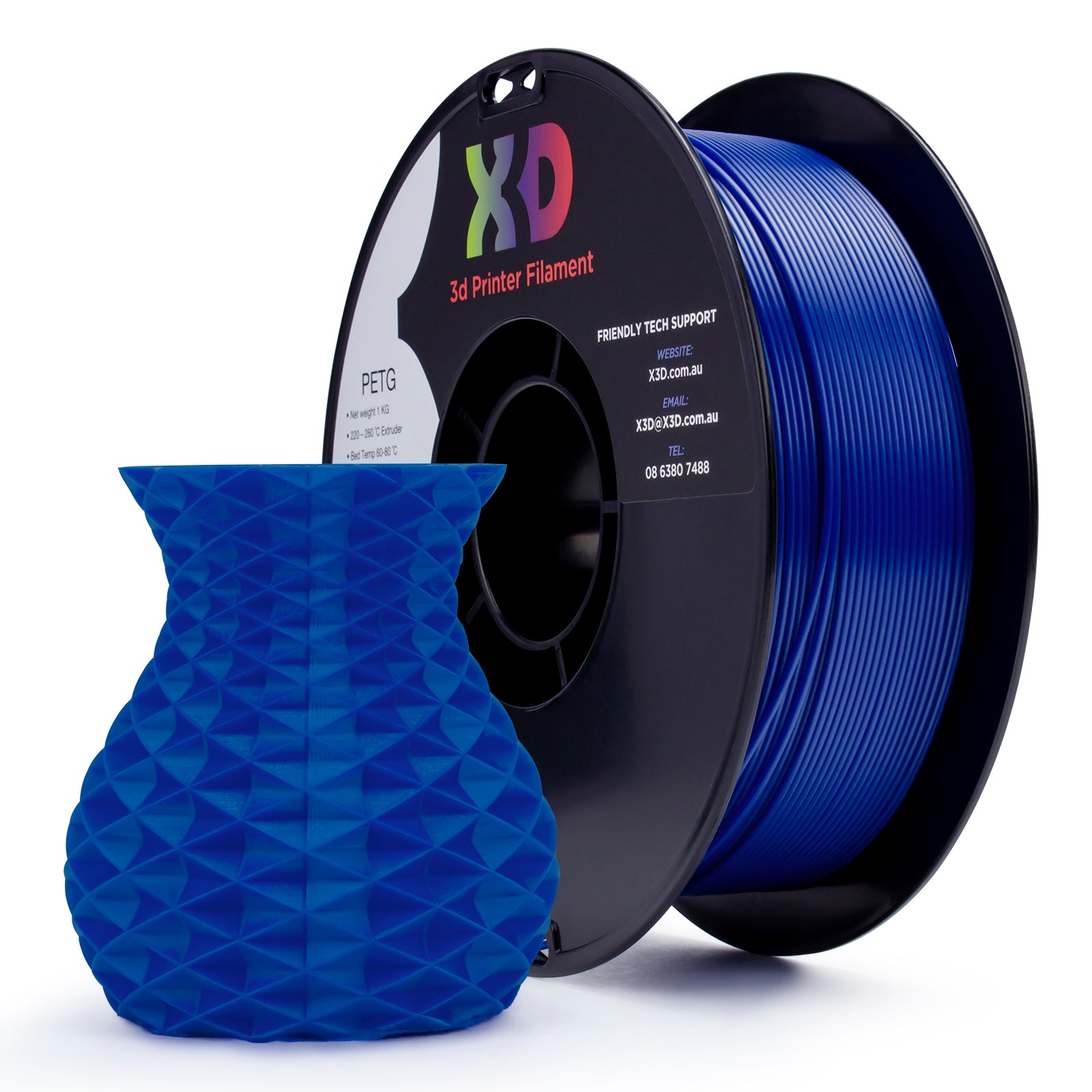

As strong as ABS and easy to print like PLA, PETG filament finds that sweet spot between the two staples of 3D filament printing. Unlike ABS, PETG doesn’t emit a toxic odour and has little problems with warping or shrinking. Another bonus is its great layer adhesion ability, its resistance to alcohols and solvents along with it being more lightweight and flexible than ABS or PLA. Despite being a softer material than both ABS and PLA, it is incredibly strong with an impact resistance which far exceeds regular PLA prints.

RoHs compliant and tested for quality on our X3D range of 3D printers X3D Premium is the professional filament of choice. It also comes with a no fuss return or refund guarantee.

So what is PETG?

PETG (also called co-polyester) is a modified version of PET which is a plastic resin. It is the most commonly used plastic in the world. Its found find fibers in clothes, containers for liquids, foods, thermoforming for manufacturing, and in combination with glass fiber for engineering resins.

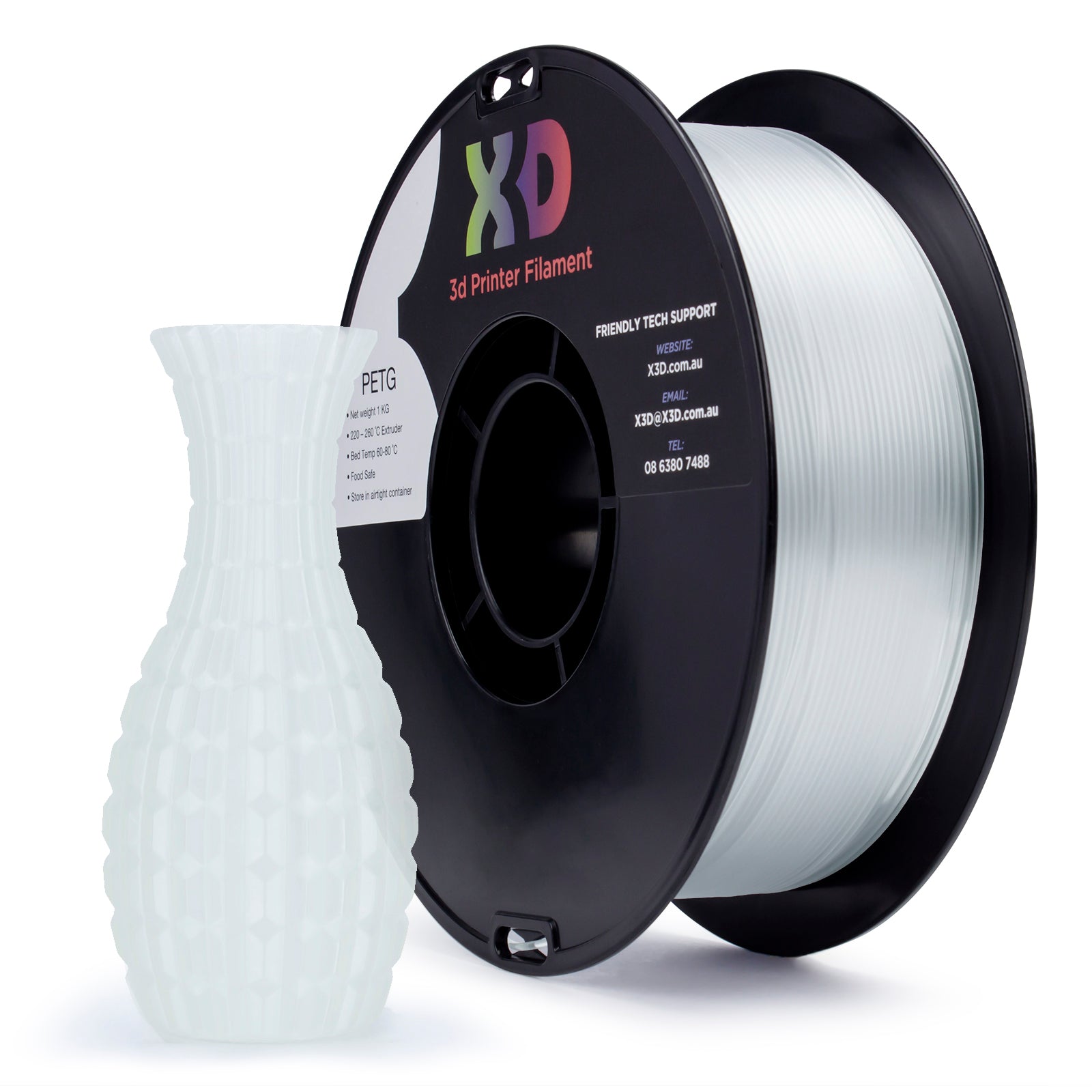

The modification into PETG is achieved by adding a second glycol during polymerization. The molecular structure is irregular; the resin is clear and amorphous with a glass transition temperature of 88 C (190 F). If you’re into chemistry, it’s known as Polyethylene Terephthalateco-1, 4-cylclohexylenedimethylene terephthalate.

What are the benefits of PETG?

It’s more durable than regular PET which can also look hazy and become brittle. The added glycol prevents the material from crystallizing and becoming breakable. The new material is also highly impact-resistant.

These are the benefits of PETG filament for 3D printing:

- PETG filament has the reputation of combining the benefits of ABS (stronger, temperature resistant, more durable) and PLA (easy to print) in one material.

- The layer adhesion is usually excellent.

- You can expect less trouble with warping or shrinking of your prints.

- Also, you can have the material, prints and misprints recycled.

- It is considered to be food safe in nearly all countries.

Any drawbacks?

There aren’t many. First of all, it’s more prone to scratches than PET. Also, it can be weakened by UV light. Some makers say it’s not the easiest material to print with, as you have to find its “sweet spot”.

Printing Parameters

- 220-250 C Extruder

- Bed temp – 60 – 80 C

Features

- Smooth and Consistent Print

- Extra Strong

- High Impact Resistance Quality

- No Harmful Additives and RoHS compliant

- Consistent Quality from Reel to Reel

- 1kg Roll

Specifications

| Spool Size | |

| Inner diameter | 53.5mm |

| External diameter | 200mm |

| Thickness | 64mm |

Storage

Store filament away from the sun and in a sealed plastic bag with the silicon moisture bag inside.

Pricing

Price inclusive of GST

Fast Shipping

X3D are committed to keeping shipping prices low so our customers can always get the best quality products on time and at the most reasonable prices.

Check out our shipping options.

We are transitioning to cardboard spools so you may get plastic, cardboard of a mixture of both