The first layer can make or break a 3D print. The first layer serves as a foundation for the whole print. If it’s not up to scratch, the succeeding layers will not be laid out properly, thus, ruining the whole print. You have no choice but to get rid of it and restart the printing.

With so much riding on the first layer’s shoulder, you have to ensure that everything goes well. If you have already done all the 3D printer prep to guarantee a successful first layer, you might as well employ these three bed adhesion tricks: using rafts, skirts, and brims.

What are rafts, skirts, and brims in 3D printing?

They may sound like parts of clothing, but they’re not. They are printing techniques that you can find in your slicer program to improve the first layer printing. Each serves a different purpose and addresses different problems. Here are the differences between each one.

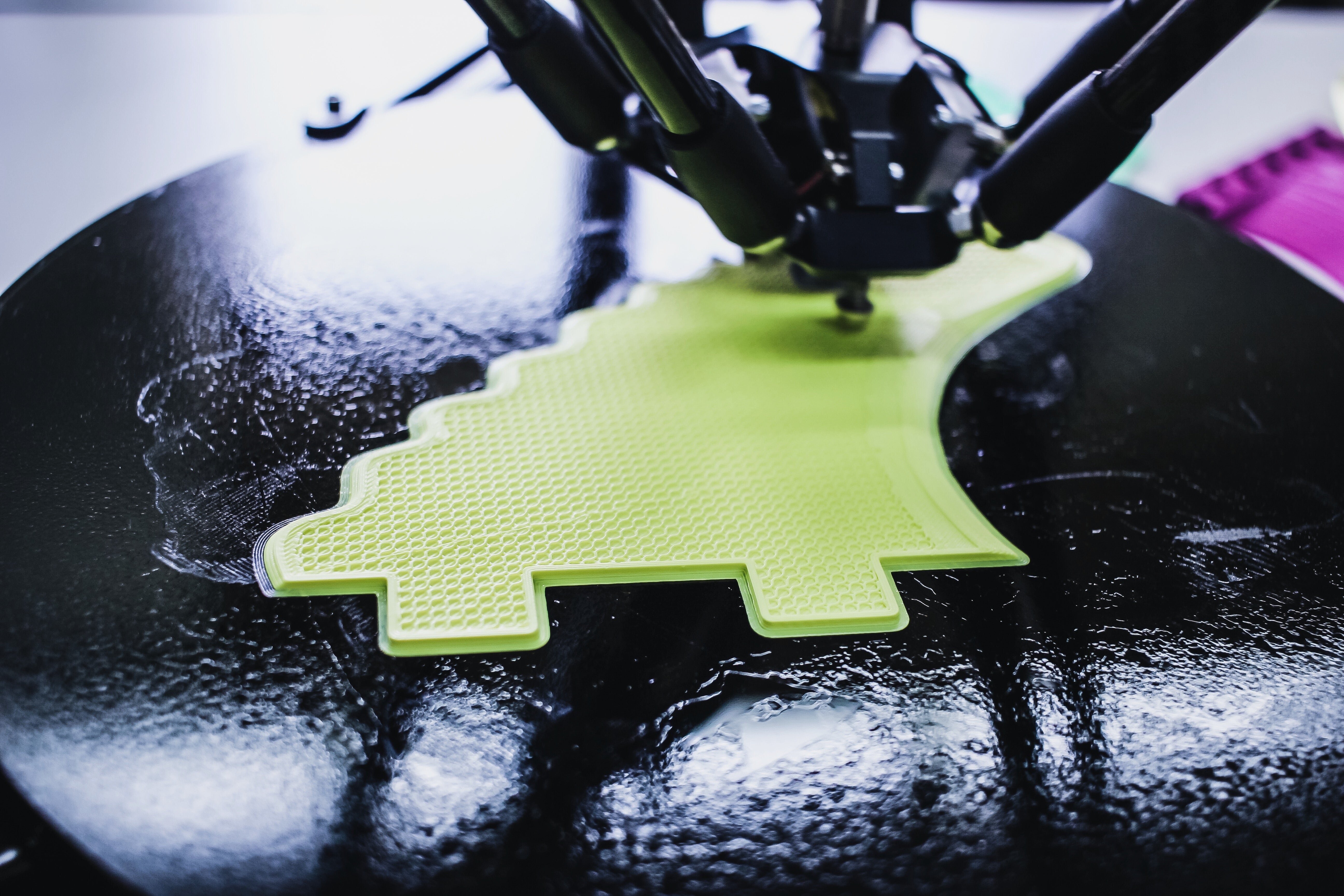

Rafts

(Source: Ultimaker)

The 3D printing raft is printed beneath your 3D model. It can sometimes be made of multiple layers, depending on the need of your design. Basically, it is the first layer of your print since it is printed directly on the build platform, making it the foundation of your 3D print instead. Rafts work best with ABS as they fix the filament’s warping and bed adhesion issues. It is also similar to support structures as they help stabilise designs with small footprints and improve its adhesion to the bed.

Benefits and Limitations of Rafts

Benefits:

- Makes ABS and other similar filaments easier to print with as it reduces the filament’s risks of warping

- The best method at improving bed adhesion

- Builds a more solid foundation for your 3D prints

- More consistent output

Limitations:

- Similar to supports, it can be difficult to remove and leaves marks on the prints upon removal

- It is also possible to accidentally destroy the model while removing the raft

- It uses up additional material

Skirts

(Source: Ultimaker)

Instead of sticking to the 3D prints, a skirt is printed to outline the edges of the 3D print. It is not connected to the 3D print at all; therefore, it does not support the print in any way. What it does is warm up the extruder to ensure a smooth flow of extruded filaments. It also serves as a test print that can signal you if there’s anything wrong with the bed adhesion and leveling, allowing you to adjust the settings to resolve the problems before printing your project.

It can be used with any type of 3D printing project.

Benefits and Limitations of Skirts

Benefits:

- Warms up the extruder

- Helps you identify potential printing issues before printing your project

- Uses less material than the other two techniques

Limitations:

- Requires additional material

- Does not help the print in any way other than helping detect potential issues

Brims

(Source: Ultimaker)

A brim is similar to a raft as it is attached to the print. The difference is that a brim is only attached to the outer edges of the print similar to a brim of a fedora hat (hence the name).

Just like rafts, it improves bed adhesion and warping. It also supports the support since the latter sometimes can be too small to stand on its own.

Benefits and Limitations of Brims

Benefits:

- Prevents the warping issues of hard-to-print filaments such as ABS

- Improves bed adhesion

- Doesn’t damage the print as much as rafts

- Easier to remove than rafts

- Doesn’t use as much material as rafts

Limitations:

- Uses up additional material which incurs additional production costs

- Still leaves a few marks on the print upon removal, which can be sanded out

- Print may accidentally be ruined when removing the brims

First layer problems no more with these Bed Adhesion Tricks!

Improving bed adhesion is key to the success of your 3D prints. Another trick that can help ensure consistent prints is by using high-quality 3D printer filaments. If you are in need of 3D printer filaments that produce strong and impact-resistant 3D prints and deliver consistent results, check out our range of X3D Pro filaments. We offer a 100% Satisfaction Guarantee on them — if you are not completely happy with them, we will replace or refund you for free! For inquiries, contact us by phone or email.