When you think of Ultimaker, you think of the best 3D printers on the market. There is no other brand that comes close to the superior quality, performance, ease of use, reliability, and support that it provides. Their 3D printers are worth the more expensive price tag compared to other brands on the market.

With the two latest releases, Ultimaker S3 and S5, you can expect the same things. However, it can be pretty hard to decide between the two. At first glance, the only discernible differences are the size and price. However, they cater to two different audiences. How do you know which Ultimaker 3D printer is right for you? Read more below to help you decide.

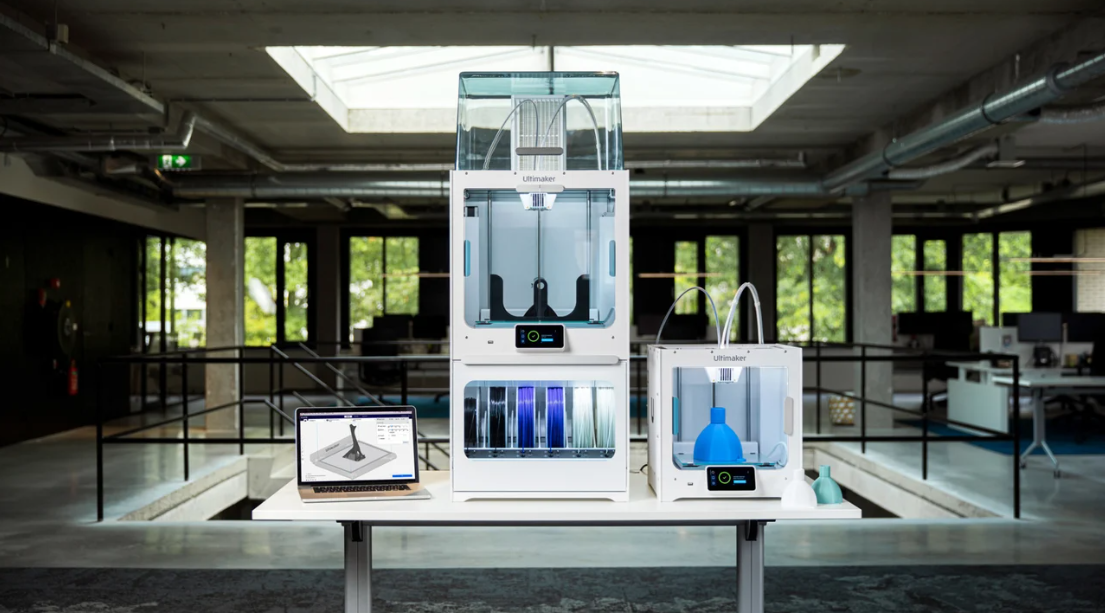

Ultimaker S3 vs S5

Both of the Ultimaker printers have a lot of similarities. However, the most recent S5 has upgrades that improve its printing efficiency .

- Build volume: Ultimaker S5 has the upper hand as it has a larger capacity with 330 × 240 × 300 mm (13 × 9.4 × 11.8 inches) vs S3’s 230 × 190 × 200 mm (9 × 7.4 × 7.9 inches).

- Non-stop filament flow: S5’s Material Station add-on allows for humidity-controlled storage of 6 filament spools that automatically feeds into the printer for 24/7 printing.

- Stronger feeder wheels: The S5’s feeder wheels are capable of printing abrasive materials made of glass and carbon fiber. On the other hand, the S3 can only print composites of these materials if you install its abrasives-resistant print core, CC Red 0.6.

- Air filtering: Another S5 add-on is the Air Manager which filters up to 95% of all ultrafine particles (UFPs) emitted during 3D printing and forms a safe, physical barrier to the print area.

With these in mind, let’s discuss the similarities between S3 and S5 and what they could mean.

Similarities between Ultimaker S3 and S5

The Ultimaker S5 has significant improvements but it doesn’t necessarily make it better than the S3. Here are the similar features between the two Ultimaker 3D printers.

- High resolution: Both have 20-micron (0.001 inch) layer resolution which captures fine ultra-fine details.

- Dual extrusion: These two printers have a dual extrusion feature using print cores. It lets you print a model with two different filaments at the same time.

- Ease of use: Both of Ultimaker S-series printers are easy to use without the need for tweaking or troubleshooting. They are plug-and-print right out of the box. Operating it is so simple that everything can be done with the touch of a button.

- Filament run-out sensor: Both have end-of-filament sensors that pause the print and alert the user once the filament has run out or jammed.

- Active Bed Leveling: This feature measures the entire build plate before each print and automatically compensates for any level inconsistencies across the area.

- Front door: This front door maintains the temperature inside the printer during printing.

- Modern touch display: They have a large 4.7-inch color touch screen interface where the user can control the printer. The interface design is so good that it won the iF Design Award 2019.

- Connectivity: The recent Ultimaker 3D printers can now serve as a network host, thanks to its Cura Connect portal. It connects print jobs to any compatible printer on its local network.

- Open filament system: The printers are now compatible with any filament with a width of 2.85 mm material.

Conclusion

Both the Ultimaker S3 and S5 are high-performing 3D printers but what you choose depends on your purpose. If you need a 3D printer for personal use or small volume production, the Ultimaker S3 will be the right one for you. However, industrial applications and mass productions are better suited for the Ultimaker S5.