3D printing technology is at the forefront of rapid prototyping and additive manufacturing. But did you know that there are different kinds of 3D printing? Today, we’ll discuss DLP and FDM 3D printing, two of the most popular methods for consumer 3D printers. Read more below to find out which type of 3D printing is the right one for your projects.

FDM Printing Explained

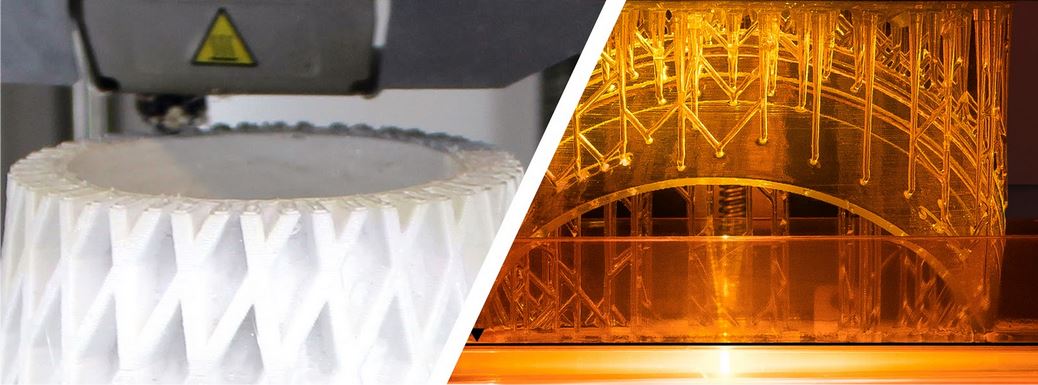

FDM (Fused Deposition Modeling) printing is the 3D printing method that we’ve all come to know and love. Its mechanism is pretty straightforward: a filament (made of thermoplastic) is fed through a heated extruder and deposited in layers to create an object. The heat makes the filament soft therefore it oozes out like a paste.

It is the 3D printing technology that most consumer-level users favour. FDM printing is available at different price points, from affordable to expensive. Its filaments are also relatively cheap. You can find a high-quality PLA filament for as low as $30 on our website.

With FDM 3D printing, its filaments come in different types of thermoplastics and colours. Some of the variants include PLA, ABS, PETG, Polycarbonate, ASA, Nylon, HIPS, TPU, Carbon Fiber, and PVA. There are also specialty filament blends, such as Wood, Filament, recycled plastic, and stone.

Resin Printing Explained

Resin printing is a far cry from the FDM printing. Instead of extruding a melted filament to build layers of an object, resin DLP printing involves resin being solidified by a UV light until it forms an object. It usually builds an object from top to bottom, which can be pulled out of the resin vat upwards with the print bed.

DLP printers are more expensive than FDM printers. Their resins are also more expensive and require more to use. However, resin printing has its redeemable qualities, which make many artists and 3D print craftspeople prefer it more than FDM printing.

Differences between FDM and Resin Printing

1. Resolution

The first thing you’ll notice about FDM and resin prints is their resolution. You’ll find that resin printing creates higher-resolution objects, thanks to the pixel density of the light source (projector). This makes it ideal for 3D model creations, jewellery, dental prosthesis, and millifluidic devices.

On the other hand, FDM printing involves extruding filament from a nozzle so the layers don’t make for high-resolution objects.

Winner: Resin Printing

2. Quality of finishes

Resin printing also has a smoother finish. FDM prints tend to have layer lines as they are printed by layers.

Winner: Resin Printing

3. Ease of use

There is a reason why FDM printing is preferred by most 3D printing enthusiasts. FDM printing is easier to use. Some FDM printers are even plug-and-print. Resin printing involves a lot more processes: extensive setup, post-processing, and curing.

Winner: FDM Printing

4. Strength of prints

DLP printing’s high resolution and smooth finish come at a cost. Its prints tend to be more fragile due to the resins used. Meanwhile, FDM printing has engineering-grade filaments that are made for tough applications.

Winner: FDM Printing

Which 3D printing works best for you? FDM or resin printing?

There is no right or wrong answer about which is better between the two. It depends on what you need for your 3D printing project. If you need functional pieces for tough applications, FDM printing is the best for you. Resin printing is ideal for 3D model creations, jewellery, dental prosthesis, and millifluidic devices.