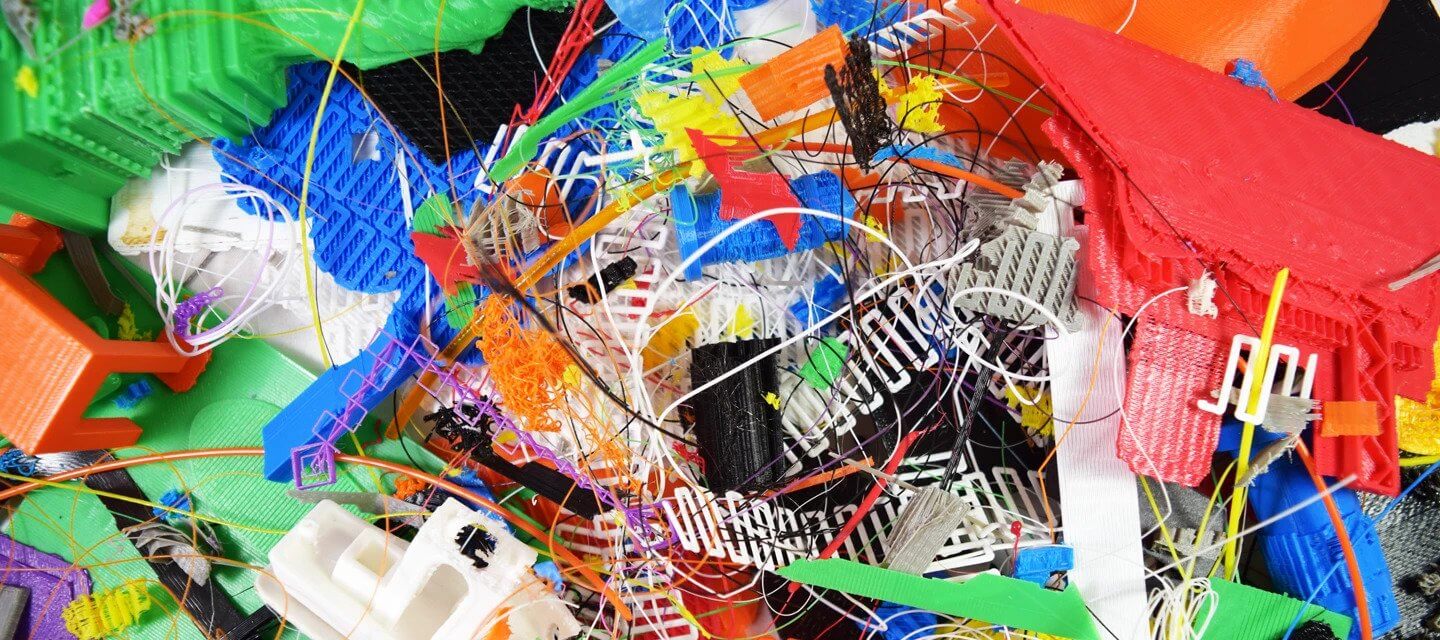

As 3D printing becomes more popular, concerns about its sustainability and environmental impact are also on the rise. Since the technology uses thermoplastics, how can we minimise the waste created during the printing process? In this blog post, we'll take a look at how you can recycle the two most popular filaments, PLA and PETG filaments, to reduce waste and contribute to a more sustainable future.

What are PLA and PETG?

PLA is an eco-friendly material made of biodegradable thermoplastic sourced from renewable resources such as corn starch or sugarcane. It is one of the most commonly used materials in 3D printing due to its low toxicity, easy printability, and low warping.

On the other hand, PETG is a modified version of PET (polyethylene terephthalate) that contains glycol, making it more durable and flexible. It is also commonly used for 3D printing due to its excellent strength, clarity, and ease of use.

Can PLA and PETG Filaments Be Recycled?

Since 3D printer filaments are made of thermoplastics, they can easily be melted down and recycled. However, not all types of plastics are accepted by recycling plants. Each one has different rules about the plastics that they can process so it is best to check with them first if you’re planning to send your 3D printing waste to your local recycling centre.

That said, the rules vary for different 3D printer filament types. The most commonly used PLA and ABS filaments aren’t accepted by most curbside recycling programs as they are classified as Type 7 under the ASTM International Resin Identifier Codes.

Meanwhile, PETG isn’t accepted by most programmes either. While it is similar to the material that creates plastic bottles, PETG can’t be mixed with them.

Most 3D printer filaments are also classified as Type 7 except for Polypropylene (PP) filaments. However, there are only a few municipalities that recycle them. Contact them first before turning in your failed 3D prints.

What Can We Do to Recycle PLA and PETG Filaments?

Even though most local municipal recycling programmes don’t process 3D printer filaments, we still have options! Here are some recycling methods that you can do yourself (or with a little outside help) to repurpose your PLA & PETG wastes.1. PLA Composting

The good thing about PLA is that it’s a biodegradable material, which means it can easily be broken down over time. We can compost PLA filaments on our own, although it will take some time.

On average, PLA filaments break down within 12 weeks, but it still depends on the thickness of the material. If you are trying to compost a thick PLA 3D print, it will take longer than 12 weeks. If your 3D print is made of a thin film of PLA then it’s more likely to be composted within the 12-week period.

2. Filament Re-Extrusion

Another way to recycle filament wastes is by re-extruding them. Fortunately, filaments can be melted down and reused for your next 3D printing project. You only need to purchase a filament extruder and you can have your very own filament maker, which saves you money in the long run.

Filament re-extrusion requires two steps: first is shredding the plastic into small pieces. You can use a blender or meat grinder to break down the filaments. Second, melt and extrude the pieces with a filament extruder. Check out Filabot’s Filament Extruders and ReDeTec’s ProtoCycler+.

3. Optimise 3D Printing Settings

There are also ways that you can do during the 3D printing process to reduce plastic waste buildup.- Avoid using rafts: Rafts help your 3D prints stick to the bed during printing. However, they use a lot of materials that will end up getting tossed into the bin after printing. To improve bed adhesion, you can use brims instead to save up on filament. You can also adjust the first layer height.

- Reduce the support structure: Similar to rafts, supports waste a lot of filaments. You can design your models to use the least amount of supports possible whether adding minimalistic supports into the part itself or trimming the number of supports manually with the use of Simplify3D.

- Don’t skip your routine 3D printer maintenance: Keeping up with your 3D printer maintenance can prevent failed 3D prints.

- Use a remote printer monitoring system: 3D printing is a long process, so naturally, you will have to leave your 3D printer running unattended at some point. You can supervise your ongoing printing project remotely with the Ultimaker 3D printers as they are equipped with a video cam.

- Avoid printing a huge batch: Printing too many parts in one go is a quick recipe for failure since if one part fails, the others will be guaranteed to fail as well. What you can do instead is separate multi-component parts into multiple runs.

- Use recycled filaments: Choosing recycled filaments for your 3D printing projects reduces the consumption of raw materials. We carry numerous recycled filaments, such as X3D Pro Recycled PLA, FormFutura Reform rPET (PETG-based material), PolyTerra PLA, and FormFutura Recycled Titan X (ABS-based material).