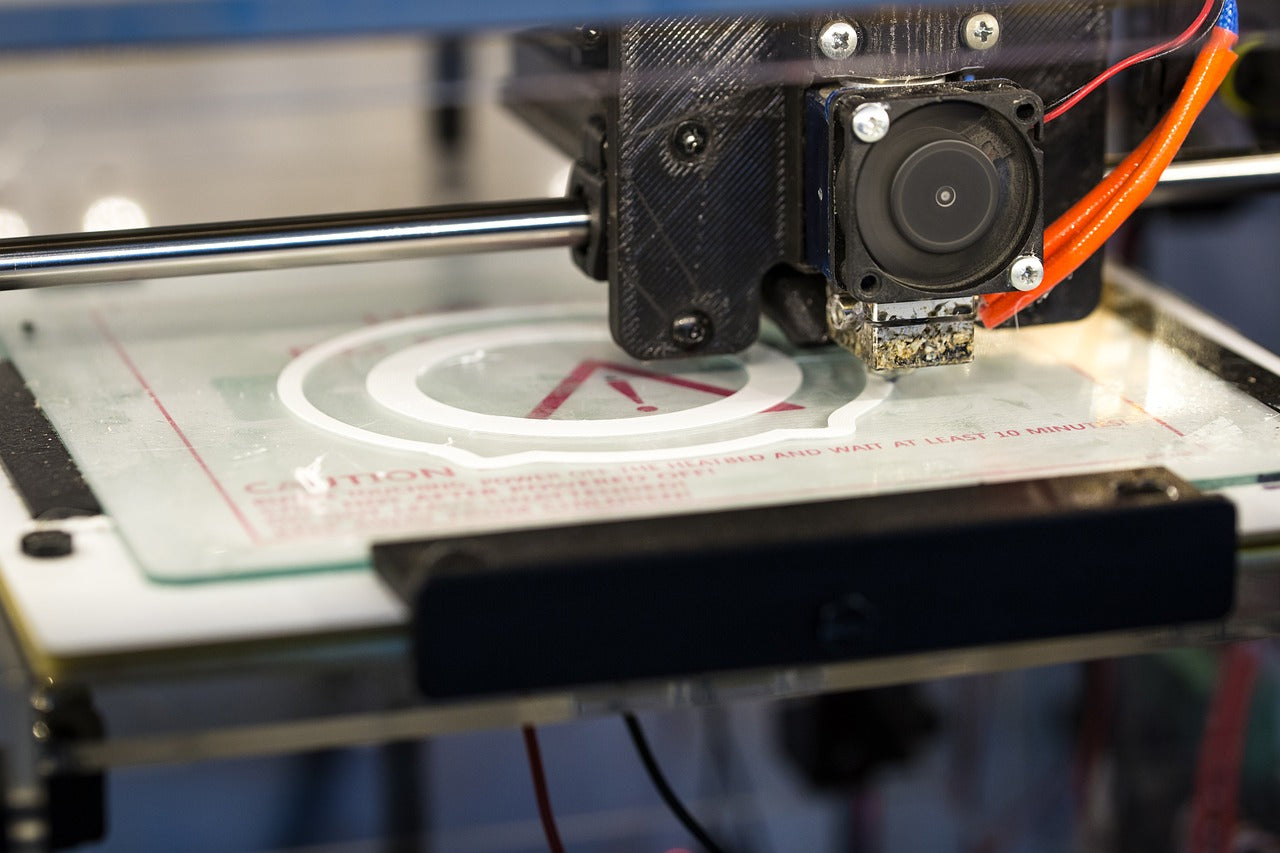

As a part that constantly comes into contact with molten filament, a 3D printer nozzle is always in high risk of getting clogged. Add to that the many factors to increase the likelihood, such as the viscosity of the filament and the size of the nozzle. There is no escaping it; there will come a time where you’ll eventually encounter clogging. Good thing, we are here to help! Here are the top tips to flushing out the clog from your 3D printer nozzle.

Causes of Clogged 3D Printer Extruder Nozzles

Clogging of 3D printer nozzles is natural and bound to happen whether you like it or not. Here are the reasons why:

- Dust and dirt buildup: The accumulation of dust and dirt inside your nozzle is inevitable. When the molten filament travels down the nozzle, it takes the dust and dirt along with them, melting them and turning them into carbon. Sooner or later, the latter will get stuck at the bottom, which will block the flow of the filament and cause your nozzle to be clogged.

- Cheap filament. While there are budget-friendly filaments that are well made, it is the low-quality ones that you should be wary of. Cheaply made filaments do not undergo a strict quality control, so they may have inconsistent widths throughout the strand and a high composition of filler material and contaminants.

- Wrong Print Temperature: The print temperature affects the consistency of the filament. Too hot and it causes heat creep, an occurrence that happens when the heat extends upwards beyond the hot end. It softens and melts the filament before it reaches the end of the extruder, therefore requiring more pressure to secrete it. PLA and related filaments also tend to crystallize in the nozzle in high temperatures. If the temperature is too low, the filament will not melt thoroughly, and parts of it will just turn into a sticky goo that will adhere to the interiors of the nozzle. It will put more pressure on the printer head to secrete the filament. Due to the pressure, the extrusion motor will have difficulty in feeding the filament into the head, which will then cause the dreaded clogging.

- Too Low Nozzle Height: The nozzle height influences the success of your 3D prints. Some filaments work well with low heights while the others need to come from a higher height in order to have a good bed adhesion. However, if the height is too low, it will cause the molten filament to back up into the nozzle as it wouldn’t have enough room to come out.

3 Ways to Unclog Your 3D Printer Nozzle

Poking around with guitar strings or needles

This method works especially great if the clogging isn’t that bad and there’s just a small around of residue. Use a hypodermic needle or guitar strings that is smaller than the size of your nozzle so that it will fit. Heat up the hot end and use a pair of pliers to pick up the B or high E guitar string or hypodermic needle to insert it into the nozzle. Move it back and forth carefully until the clog is broken through and removed.

Solvent Soaking

If the clog is made up of soluble material, you can try to submerge it in the appropriate solvent to melt it down. Find out if the filament is soluble, such as ABS which can be dissolved by acetone. What you only need to do is remove the nozzle from the 3D printer and soak it in the solvent for 24 hours, while shaking it every couple of hours. You can then get a guitar string or needle to poke out the clog. If it still doesn’t budge, leave it in the solvent for another 24 hours.

Cold Pulling

Cold pulling is best suited for when your nozzle has carbon or carbonized material buildup or when the clog is caused from going from high to low temperature while printing. It is advisable for ABS, PLA, and Nylon filaments. It can be a time-consuming method and put a lot of stress on your machine though.

It is aptly called cold pulling because it uses a cool-enough filament to keep it in one piece, but warm enough to have a stretchy consistency so that it can be pulled away from the sides of the barrel. It is used to pull out the blockage behind the actual nozzle hole from the back.

You start by reversing the print material out of the print head. In order to pull out the bowden tube from the print head gently, remove the clamp that holds the tube.

Heat up the hot end to the print temperature of the last filament you used (check the manufacturer’s recommendations for the temperature of the filament). Insert a 20cc-length filament all the way down into the print head. If it is not inserting further or not extruding properly, feel free to apply a touch of pressure. Next, lower the print head temperature to 145C for higher temperature materials and 110C and 90C for ABS and PLA, respectively. Wait for the head to cool down to the desired temperature. Once it is cool, pull the print material in one quick and clean jerk out of the print head. Keep doing this until the tip of the removed material is clean.

It can be such a hassle to clog your 3D print extruder nozzle. Fortunately, there are a lot of ways to unclog it. However, there can be times that the clog is too severe that it would be best to buy a new nozzle altogether. But this is completely avoidable. As they say, an ounce of prevention is better than a pound of cure. Our next blog post will be discussing how to clean an extruder to do away with clogs forever. If you need help with filaments or any of the methods discussed above, you can contact us by phone at 08 6380 7488.