Warping is an issue that is dreaded by both 3D printing enthusiasts and professionals. It is nothing short of a tragedy to see your 3D print ruined because of this issue. What is warping and what causes it exactly? Read below to find out.

What is warping and what causes it?

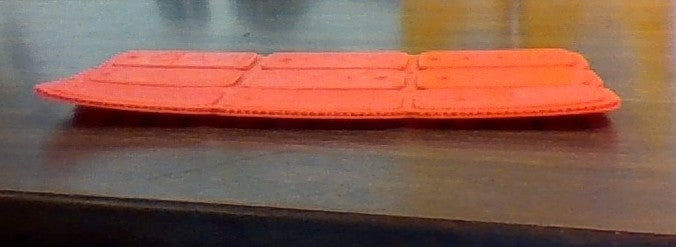

You know that warping has ruined your 3D print if you see the bottom edges curled up. This is caused by a great number of things, but generally, the filament used shrinks during the curing and cooling part of the 3D printing process. Whatever the reason may be, tension builds up within the model until the lower layers start to lift or drag. Here are the causes:

- Huge temperature differences between extruded layers

- Bigger footprint layers above the bed face layer

- High infill percentage which increases the material for shrinking

Tips to Prevent Warping

Most warping cases are brought on by uneven temperature, so the most important thing to do is making the temperature consistent and increasing the grip of the base on the bed.

- Use a heated print bed: A heated print bed ensures that the glass transition temperature is maintained. It also allows the 3D print to adhere better to the bed.

- Utilize an enclosed print chamber: It prevents the temperature from changing during the entire 3D printing process.

- Keep the room temperature consistent: Aside from making sure that the 3D printer maintains a consistent temperature, you have to make sure that there won’t be a draft coming in from the windows or door.

- Turn off the fans in the beginning: The first few layers are crucial. Turn off the fans during the printing of these layers to make sure that their temperatures are evened out to keep the 3D print flat on the plate.

- Apply bed adhesives: To prevent the bottom edges from lifting from the plate, make sure that the model has a firm grip on the build plate. Applying bed adhesives, such as a BuildTak or Dimafix Adhesive Pen does the job. However, you have to make sure that the model does not get stuck on the build plate as this would get it stuck.

- Add a brim to your design: By creating a brim in the slicer, it increases the bottom area so that it grips harder to the build surface.

- Supplement your model with a raft: Adding a raft also makes the base of the 3D printed model wider, which increases the grip on the build surface.

- Reduce the print speed: Higher print speeds introduce a host of problems such as curling and warping.

- Lower the infill percentage: Having a lower infill percentage reduces the tension that causes warping.

- Adjust the nozzle height and temperature: Layer height can influence the success of a 3D print and bed adhesion.

- Use non-warping 3D printing filaments: Lower the risk of warping by using non-warping 3D printing filaments.

Best Non-Warping 3D Printing Filaments on the Market

Some filaments are just more prone to warping than others. Reduce the likelihood of warped 3D prints by using non-warping 3D printing filaments.

Titan X

Titan X is an ABS filament that displays high performance and FDM-optimized engineering. Aside from its strong mechanical properties, it boasts of zero warping and superb first layer adhesion capabilities.

ApolloX

ApolloX is a high-strength and performance engineering filament made of industrial-grade ASA. It also doesn’t warp.

Order these Non-Warping 3D Printing Filaments today!

Tired of warping ruining your 3D prints? Follow our warping prevention tips above and use our zero-warping 3D printing filaments to banish warping. If you have any questions about the filaments, contact us at x3d@x3d.com.au or (08) 6380 7488.