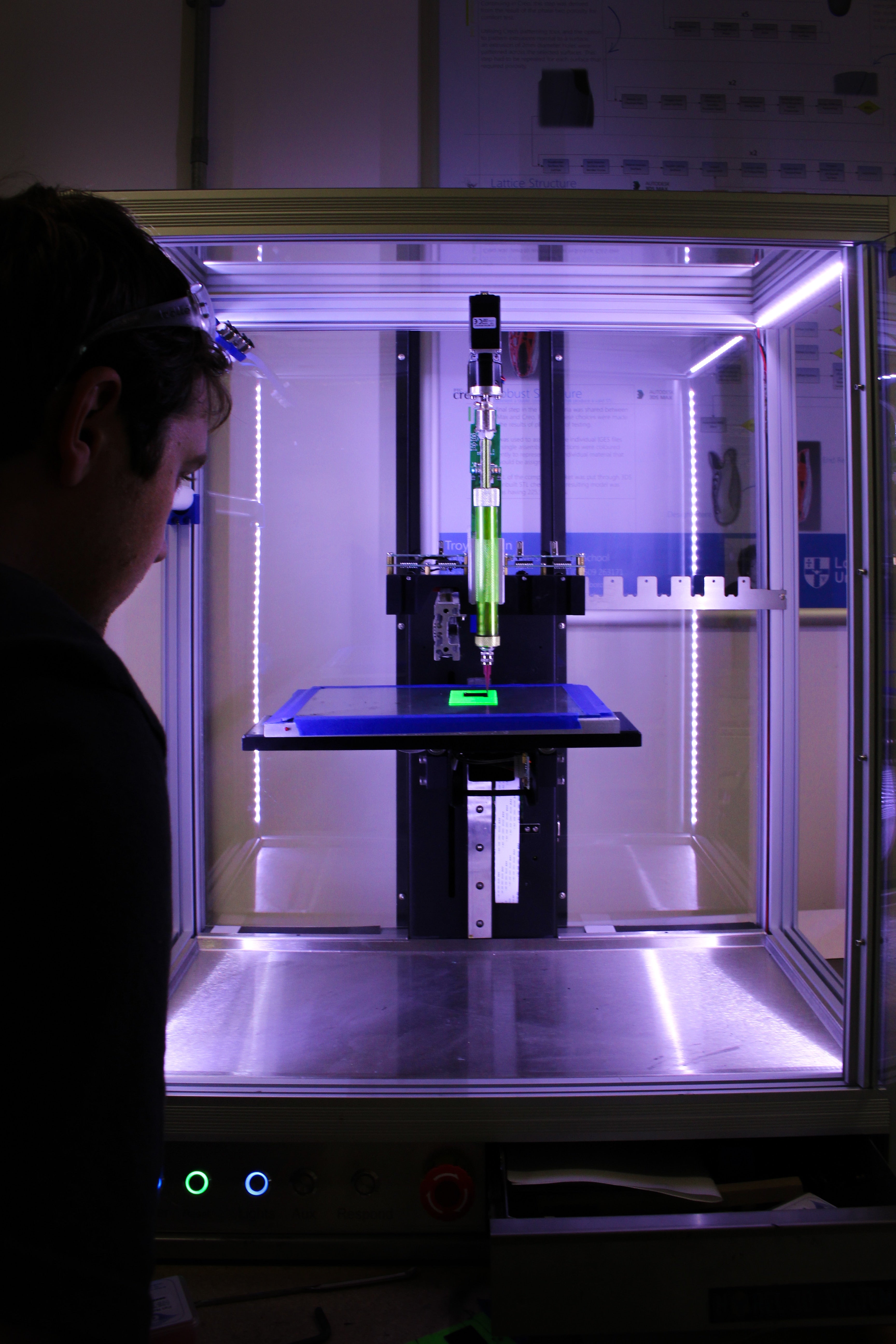

(Photo by Rob Wingate on Unsplash)

3D printers are made differently. Such is the case with the dimensional accuracy of 3D printers. No 3D printer can produce parts with the perfect dimensions. It will usually have an allowance of deviation which is called tolerance. How does this affect you? Read below to find out.

What is tolerance and how does it affect your 3D prints?

In terms of manufacturing, tolerance is the allowable difference in weight or size. It allows for a slight margin of error in the dimensional accuracy when reproducing a certain part. No matter how hard you try, there is always going to be a discrepancy between the dimensions in your design and the 3D model that you produce. It is why it’s important to determine the clearances of your 3D printer.

How does this affect you? Knowing your 3D printer’s tolerances is useful when you’re producing parts that must be joined together. When designing a 3D model, you have to consider the potential dimensional deviations. If not, it will result in poorly fitted parts or support structures.

Ready to test and improve your 3D printer’s tolerance? Let’s start with the 3D printer tolerance testing and improvement tips below.

Calibration is key to testing tolerance

You can’t find your 3D printer’s tolerance without calibrating your machine to its ideal settings. Read the instruction manual of your 3D printer to find out how. There are also templates of calibration prints that you can find online that can help you with this. Try the “Cali Cat – The Calibration Cat by Dezign (via Thingiverse)”https://www.thingiverse.com/thing:1545913.

After calibration, you can print out 3-5 copies of the XYZ 20mm Calibration Cube by iDig3Dprinting to determine dimensional accuracy. Note down the measurements for every direction (X, Y, and Z axes). For each direction, take the largest measurement and subtract it with the smallest for each direction. The median of the difference is the +/- tolerance of your 3D printer. For example, if the difference is 10, the tolerance should be +/-5.

Doubling down on the clearances

If you know your 3D printer is well-calibrated, the easy way to determine the tolerances is through finding out the clearance directly. There are templates online for 3D printer clearance testing. One such example is this free template by Maker’s Muse here.

Finetune the tolerances

Certain factors affect the outcome of the tolerances. Here are ways that you can improve them:

-

Use high-quality filaments: Cheap filaments display poor tolerances which cause extrusion discrepancies and surface issues. Use high-quality filaments that provide consistent results such as X3D Pro filaments.

* Check for deteriorating components: Worn-down components such as belts and rods cause dimensional inaccuracy. Make sure to tighten the components and replace them if they are worn out. Contact your 3D printer’s manufacturer for parts replacement. - Calibrate your 3D printer before retesting for tolerance: If you find that the initial tolerances are no longer working, recalibrate your 3D printer before measuring the tolerances again.

Start producing dimensionally accurate 3D prints with these three 3D Printer Tolerance Test and Improvement Guide!

Producing dimensionally accurate 3D prints starts with tolerance testing and improvement. If you are looking for 3D printer filaments to create your first model, check out our extensive range of 3D printer filaments here. For inquiries, contact us on 6380 7488 and x3d@x3d.com.au.