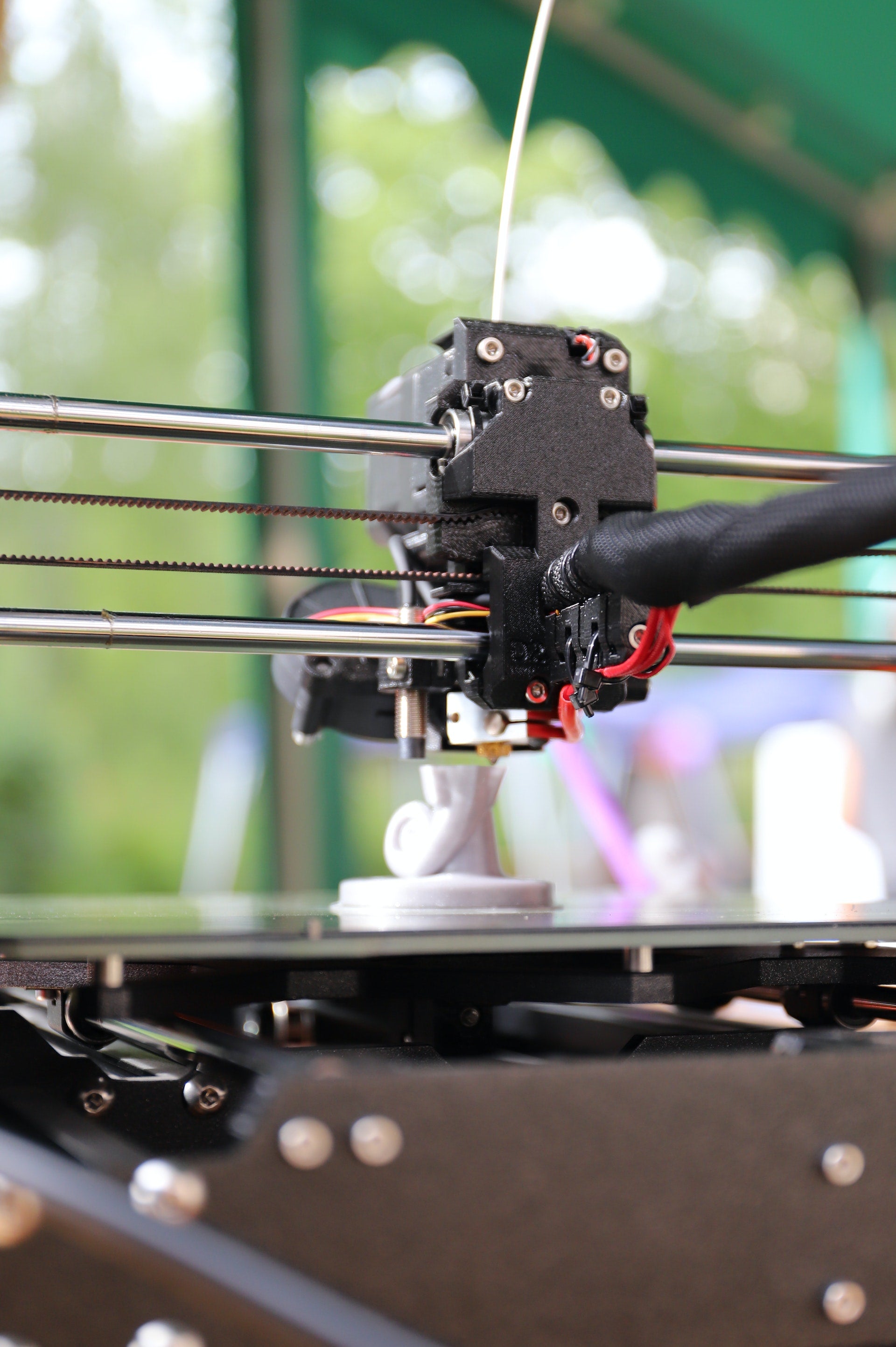

3D printing technology or additive manufacturing is becoming more popular. No longer a niche technology, its adoption rate has increased to 40% in two years, according to Formlabs’ 2022 3D Printing Applications Report. The technology is becoming more accessible to students, entrepreneurs, hobbyists, and massive factories worldwide. Does this mean you should do the same? Here are some ways that 3D printing can help:

- Improve uptime and scalability for efficient and more cost-effective production

- Easier iteration and rapid prototyping for research and development

- On-demand and on-location parts production to help solve supply chain problems

- Foster creativity and improve engagement in schools and universities with 3D-printed teaching materials

-

Increase personalisation options to meet customer demands

If you are looking to optimise and streamline your workflow, here are ways to get started with adopting 3D printing into your workplace.

1. Determine your 3D printing workload and budget

The first step is to find out what part of your company’s operations can be transitioned to 3D printing. Since 3D printers and their associated costs (manpower, training, and workroom construction) are not cheap, you need to determine if your workload justifies the costs.

If you find that your 3D printing projects are few and far between, you can outsource them to a 3D printing lab instead.

2. Find your 3D printer

There’s a different 3D printer for different needs. The printing frequency, workload volume, and budget are huge deciding factors for the 3D printer you will choose and the number of machines you will purchase. Here are our recommendations:

- Ultimaker 2+Connect: an entry-level 3D printer that’s perfect for hobbyists, small businesses, schools, and universities. It has features to improve collaboration among teams; connectivity for increased uptime; and safety to guarantee the users’ well-being.

- Ultimaker S3: a mid-level workhorse for businesses that are looking to adopt the technology. It allows for round-the-clock, high-volume, and composite-ready printing in a smaller footprint.

- Ultimaker S5 Pro Bundle: the ultimate 3D printer for heavy users, that is capable of 24/7 reliable production with increased huge capacity and end-to-end material handling.

3. Train your staff

As 3D printers are a completely different beast from the machinery you were used to, you would need to train your existing staff or hire a new one who knows how to operate a 3D printer.

If you choose to train your staff, there are many ways that they could learn. You could hire an instructor to conduct classes onsite or have them attend a 3D printing course or workshop nearby.

4. Ensure your staff’s safety in the 3D printer workroom

Some 3D printer filaments emit noxious fumes and fine particles that may be harmful to people and combustible. Therefore, it’s important to build a workroom that’s well-ventilated to keep your staff safe and healthy. Install air filters in the room to reduce the inhalation risk for fine particles. Luckily, some 3D printers are already equipped with filters like the Ultimaker 3D printers we recommended above.

Aside from having a well-ventilated workroom, here are other tips to keep your 3D printing zone safe:

- Substitute filaments: PETG, nylon, and ABS can emit fumes that can be irritating or even harmful to your staff. ABS can be easily replaced with reinforced PLA or ASA.

- Create safety guidelines: Create safety guidelines about operating 3D printers and make sure that your team knows about them.

- Have them wear personal respirators: As an added precaution or if they must print with ABS, PETG, or nylon, let your staff wear personal respirators to prevent them from inhaling the fumes and particles during printing.

Adopt 3D printing in the workplace to improve efficiency and cut costs!

There are many benefits to adopting 3D printing in the workplace. To inquire about 3D printers and materials, contact us by phone, email, or chat.