While browsing our 3D printers, you may have come across these terms. FDM and FFF are not just mere letters in the 3D printing world. These are the types of printing technology employed by 3D printers. Just what are these technologies and how do they affect the way you print? Read more to find out.

Background on 3D printing technology

There are many types of 3D printing technologies. Aside from FDM and FFF, there are other 3D printer types, such as Stereolithography(SLA), Digital Beam Melting (EBM), Laminated Object Manufacturing (LOM), Selective Laser Melting (SLM), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). Obviously, each 3D printer type operates differently. That is not the case with FDM and FFF printers though.

The difference between FDM and FFF

The reason why FDM and FFF 3D printers operate similarly is because they are the same! There are no differences when it comes to the printing processes, however FDM is a trademarked term while FFF is not.

FDM stands for Fused Deposition Modeling. It was developed by Stratasys in 1989. Eventually, the RepRap community created their DIY FDM-inspired 3D printers called Fused Filament Fabrication (FFF) so that the 3D printing community can use and discuss 3D printing without infringing on the trademark.

The science behind FDM/FFF 3D printing

FDM/FFF is the most popular type of 3D printer due to it being affordable and user-friendly. It involves feeding a 3D printing filament through its heated printer nozzle. The high heat of this nozzle partially melts the filament when extruded. However, the material immediately turns into a hardened state and binds to the layer beneath it after extrusion.

The printer nozzle moves according to a path that has been pre-set in the 3D printing software. The design of the 3D model has been divided into “slices” in the software. These slices translate into layers during printing where the printer nozzle builds on top of one another.

FDM/FFF 3D printers create 3D models that display excellent mechanical properties. They are perfect for low-volume end-use parts, manufacturing aids, and prototypes.

Try FFF/FDM 3D Printing today!

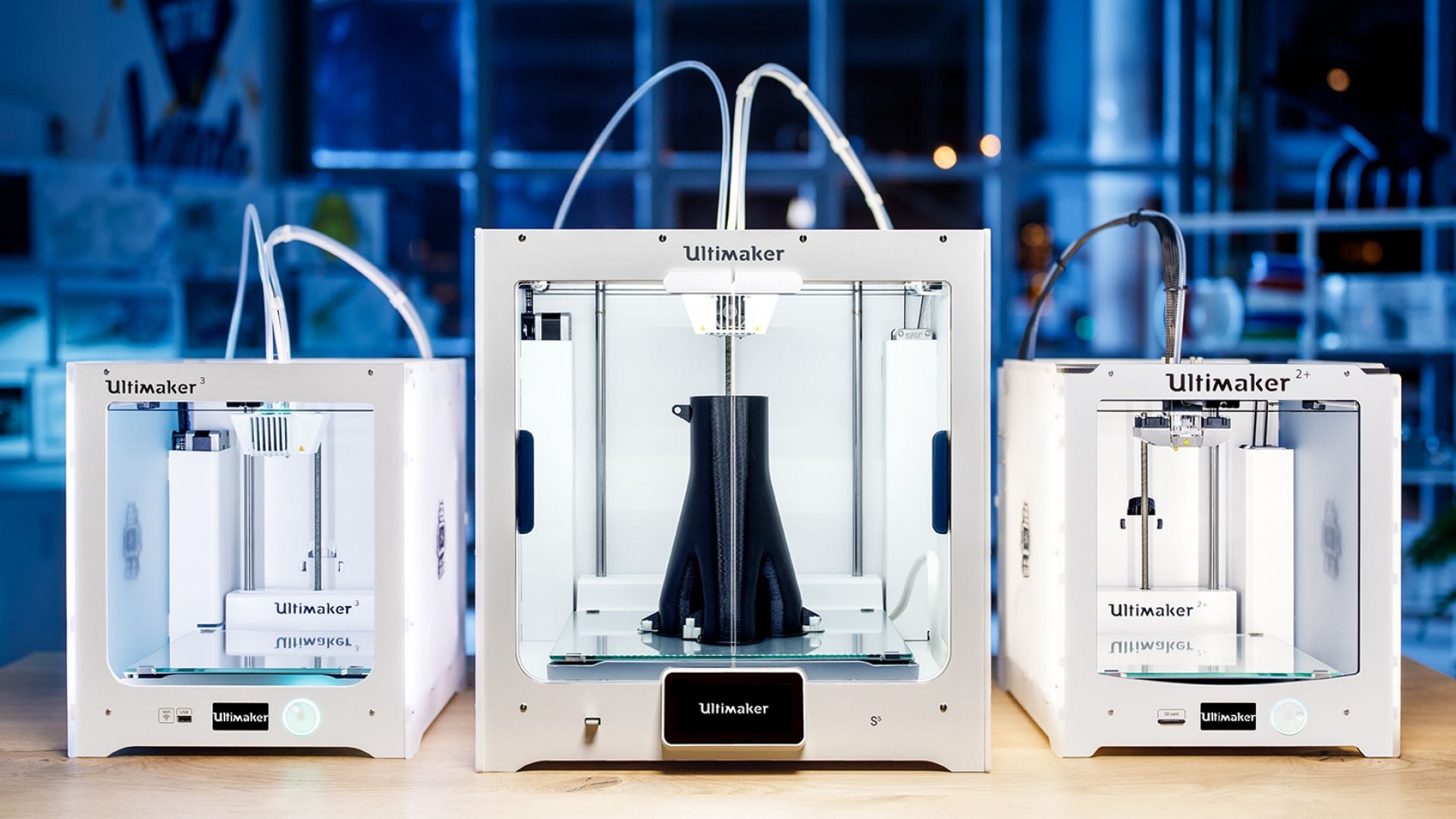

Now that you understand the difference between FDM and FFF 3D printers, you can now rest easy while browsing our extensive range of 3D printers. If you’re looking for the ultimate 3D printer, check out our Ultimaker 3D printer range.

For inquiries, you can also contact us by phone at (08) 6380 7488 or email at x3d@x3d.com.au.