Hollow 3D printing is a technique that can help you save material and cut printing time. While this method is required to make the print surface more transparent (e.g., lampshades), it can also be used to make printing projects more economical.

Here are 3 things you need to know about hollow 3D printing for FDM.

Infills

While hollow models typically don’t have infills, some type of support structure helps with the structural integrity of the object. This will especially come in handy with certain angles and shapes. However, some designs just don’t work well with going hollow.

Structural Strength

Hollowness can affect the structural integrity of the model. Infill density and wall thickness are two settings that strengthen the structure. If you need to do away with infill, make sure the walls are thick for a stronger structure.

Shell Thickness

Having a hollow object with a thin shell can cause a bad surface finish, shape distortion, and disjointed parts. In order to prevent this while minimising or doing away with infill, increase the shell thickness. You can also add a low-density infill to your design to join the disjointed parts.

Here are ways you can design hollow 3D prints.

Types of Hollow 3D Designs

1. Hollow model with solid settings

Credit: u/TheOriginal_RebelTaz via Reddit

Designing a hollow model with solid settings involves having a thicker wall. Your printer settings will treat the filling inside those walls as infill. Therefore, you can increase it using the infill percentage setting. While your object would appear hollow, it is not technically hollow due to the infill in the thick walls.

2. Solid model with hollow settings

Unlike the first one, you can design a solid model and then change the printing settings to make it hollow. Using 0% infill, removing the top layers, and thickening the shell through the slicer can turn your model hollow. This is perfect for figurines, vases, and other decorative models.

3. Patterned walls with solid settings

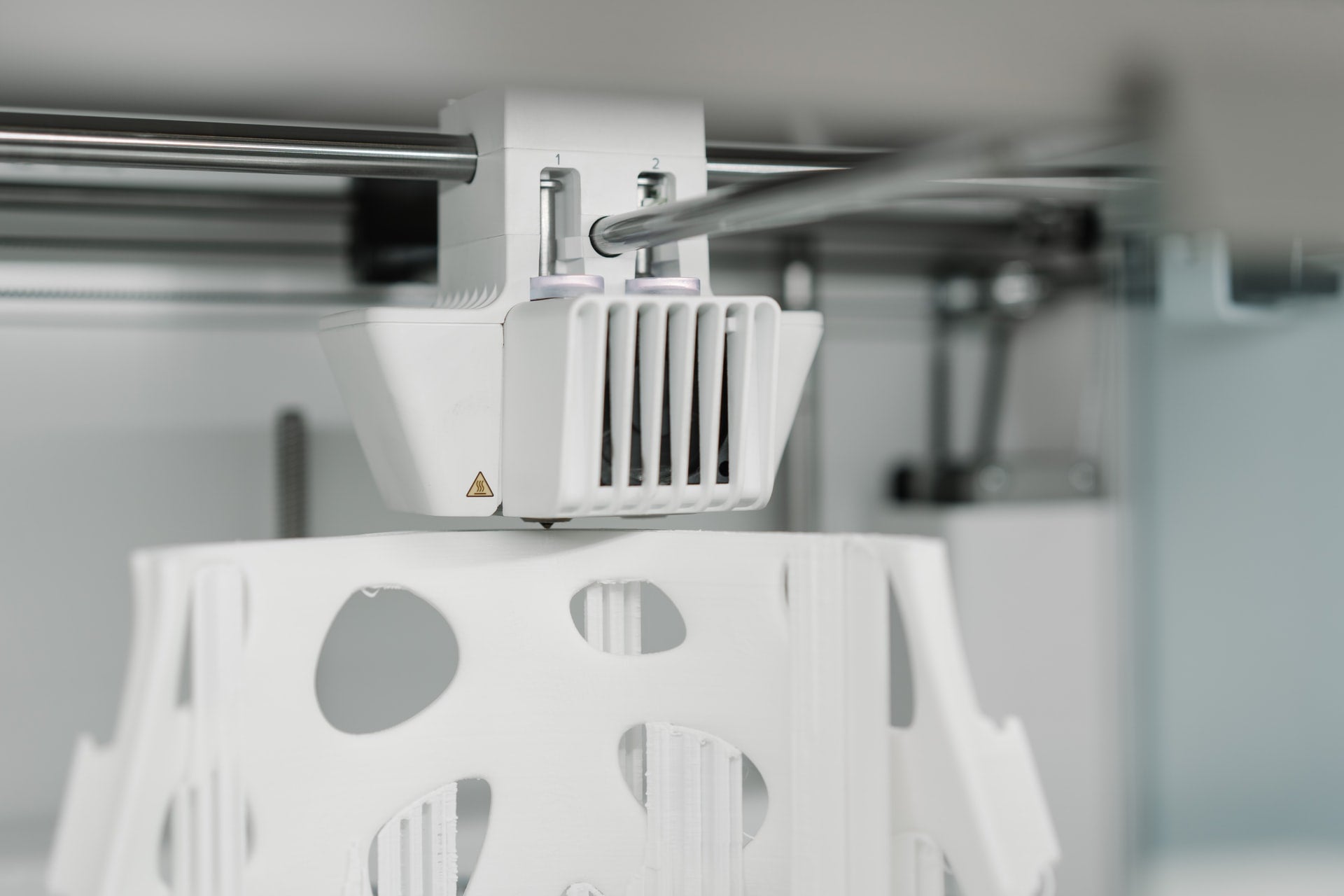

Credit: M3D via Thingiverse

Adding texture to the surface fortifies the object walls and allows the insides to be hollow without compromising strength. For example, bridges have walls with structural elements that make your design seem hollow but the printing settings are not. If you need something to be structurally sound while also being lightweight, this technique is the way to go.

Save material and time with hollow 3D printing!

Have you ever tried hollow 3D printing? Let us know how it went in the comments below!